Two types of precoat filtration exist:

Press filters: This device operates with a piston pump and consists of several plates. The plates are covered with a cloth on which the impurities mixed with the additive (often perlites or diatoms) become fixed. The pressure increases as the chambers fill.

Rotary vacuum filters: These operate by suction of the fluid to be filtered due to rotation under vacuum. The wine passes through a pre-layer of diatoms before being sucked into the drum. A scraper removes any additive or impurity accumulation during the filtration process, allowing a continuous renewal of the filtering layer. The flow rate is higher than for press filter presses.

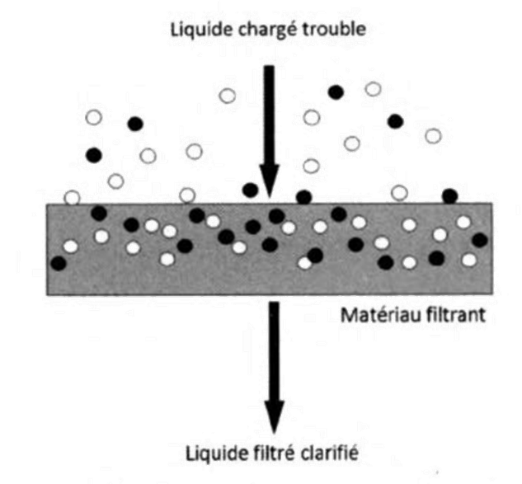

Plate filters

These systems allow the filtration of less charged liquids and are well suited to bottling, for example. Impurities are retained by sieving and adsorption. The plates (made up mainly of cellulose and then diatomaceous earth or perlite) can be of various sizes, with 40, 60 or 100 cm sides. The flow rate is generally lower than with diatomaceous earth precoat filtration (500 l/h/m2). Depending on the amount of retention of microorganisms, two types of plates can be defined:

Clarifying plates : not as close together as sterilizing plates, they have a better flow rate

- Sterilizing plates: they are more constricted, filter a larger amount of small microorganisms (such as bacteria) and have better retention than clarifying plates but therefore have a lower flow rate and a higher risk of clogging.

Lenticular filtration is also possible with plates, but the particularity of this filtration is its enclosed mounting in a hood to avoid leakage. Lenticular filtration is commonly used at the Eugenie estate and was also used at Château Latour before cartridge filters were introduced.

Membrane filters

Membrane filters enable sterile or very low-germ filtration and are used for the final filtration prior to bottling. This type of filtration consists of two filters: cartridges used as prefilters to reduce clogging and protect the membranes, and a final filtration through a membrane. The pre-filter cartridges and the membranes are attached to the base of a housing and then covered with a hood. To avoid the risk of clogging, the wine should be clarified beforehand (prefiltered or fined), which greatly improves the flow rate (about 400 l/h/m2).

The membranes can be of different sizes depending on the filtration required (sterile or not). For example, the membranes can be 1.2, 0.6 or 0.45 µm to retain yeast or even bacteria. The pre-filter cartridges can be 3 or 5 µm for example.

This type of filtration is used prior to bottling at Château Latour.